Cellulose, a natural plant polymer, is the most abundant biomass resource on earth.

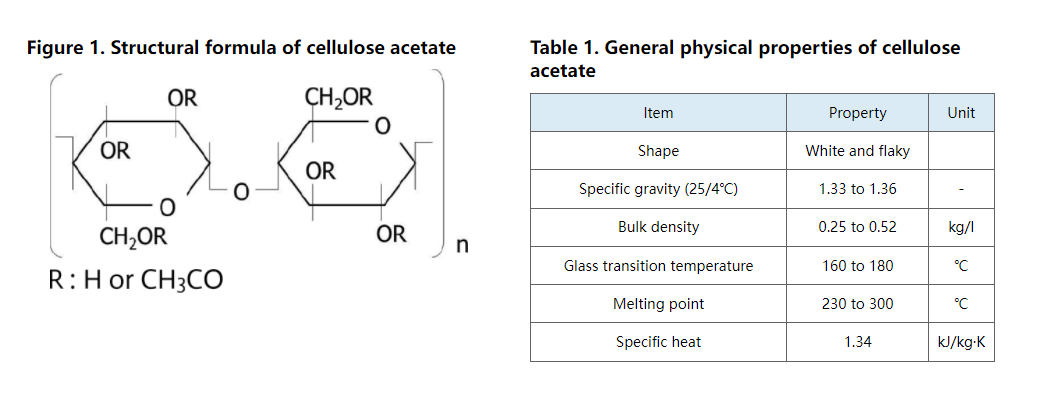

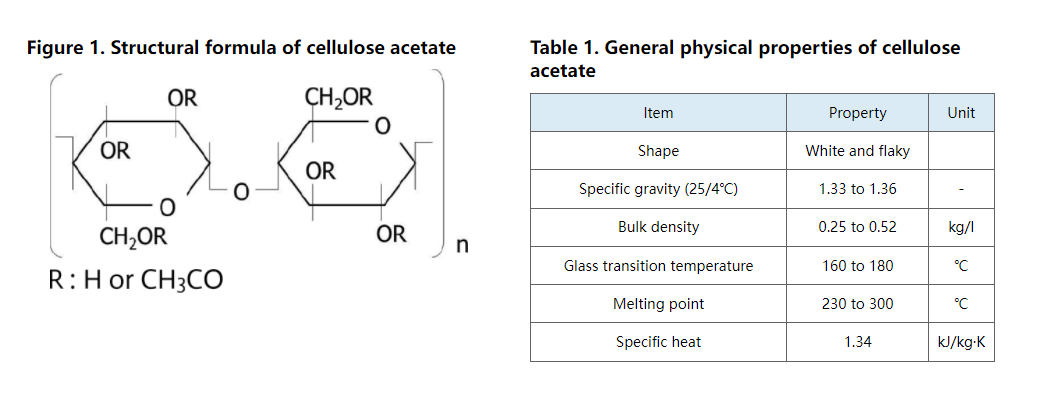

The usage of chemically processed cellulose started with the discovery of cellulose nitrate by Braconnot in France in 1833. Cellulose nitrate was mixed with about 30% camphor and plasticized to form the world’s first artificial plastic material, celluloid, about 150 years ago.Cellulose acetate was developed in 1929 as a flame-resistant cellulose derivative due to the inflammability of celluloid. Cellulose acetate is a biomass material produced by chemically modifying (esterifying) hydroxyl groups with acetic acids in cellulose materials derived from nonedible parts of plants, such as wood fibers and cotton. It is made from cellulose obtained from non-edible plants and acetic acid, the main constituent of vinegar.Cellulose acetate is a thermoplastic resin which is esterified under the action of catalyst with acetic acid as solvent and acetic anhydride as acetylation agent. Cellulose derivatives are the earliest commercial production, and the continuous development of cellulose organic acid esters.

Cellulose acetate is a biomass material produced by chemically modifying (esterifying) hydroxyl groups with acetic acids in cellulose materials derived from nonedible parts of plants, such as wood fibers and cotton. It is made from cellulose obtained from non-edible plants and acetic acid, the main constituent of vinegar.Cellulose acetate is a thermoplastic resin which is esterified under the action of catalyst with acetic acid as solvent and acetic anhydride as acetylation agent. Cellulose derivatives are the earliest commercial production, and the continuous development of cellulose organic acid esters.

What is cellulose acetate used for?

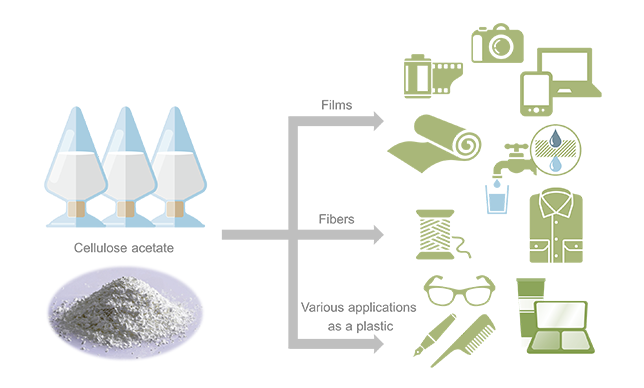

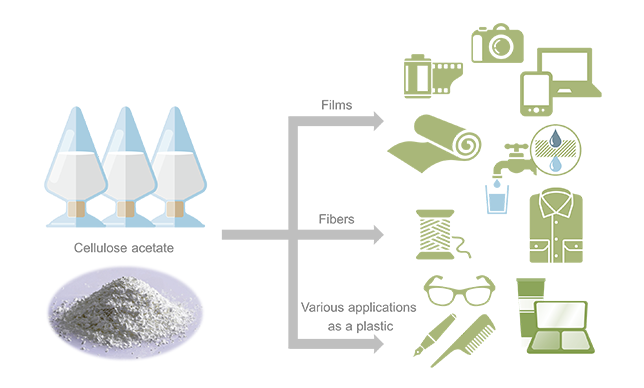

It can be processed in various ways like common synthetic plastics, and is used in wide range as a raw material for fibers, films for protecting LCDs, cosmetics and others. Cellulose acetate sheets are used in plastics such as cellulose for thermoforming main material.

Cellulose acetate sheets are used in plastics such as cellulose for thermoforming main material.

Cellulose diacetate plastic can make all kinds of tools handle, meter alphanumeric keys for computers and typewriters, telephone cases, automobile steering wheels, textile equipment parts, Radio switch and insulation parts, penholder, glasses frame and lens, toys, daily articles, etc. Do seawater desalination membrane.

Cellulose triacetate, its high melting point, can only be processed into a solution, with For film base, X-ray film base, insulating film electromagnetic, audio tape, transparent container, Diaphragm in silver zinc battery.

Is cellulose acetate biodegradable?

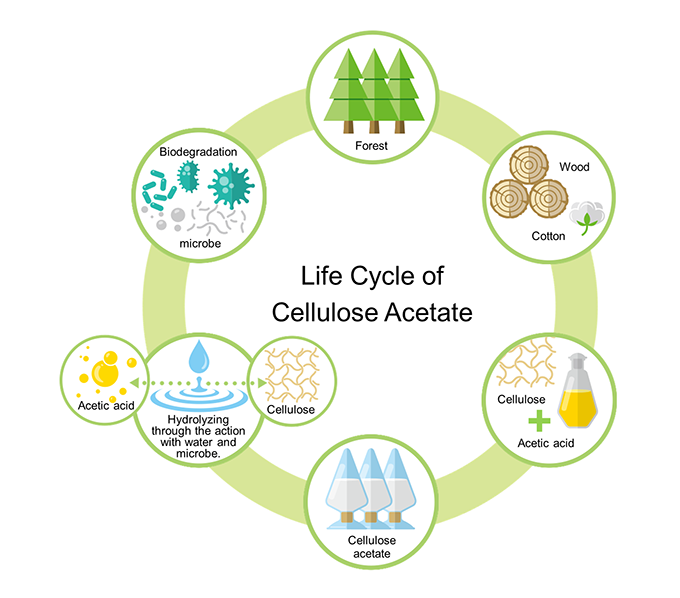

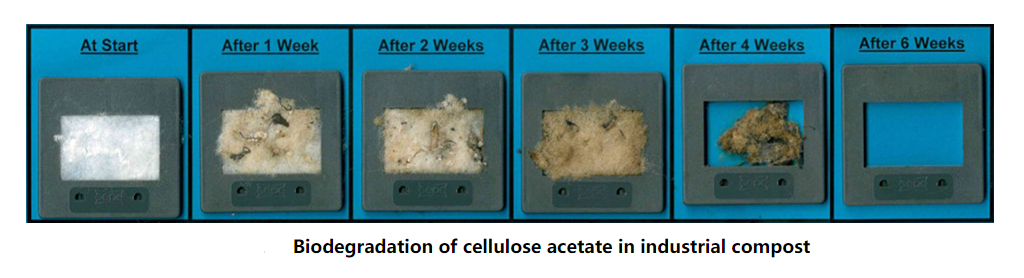

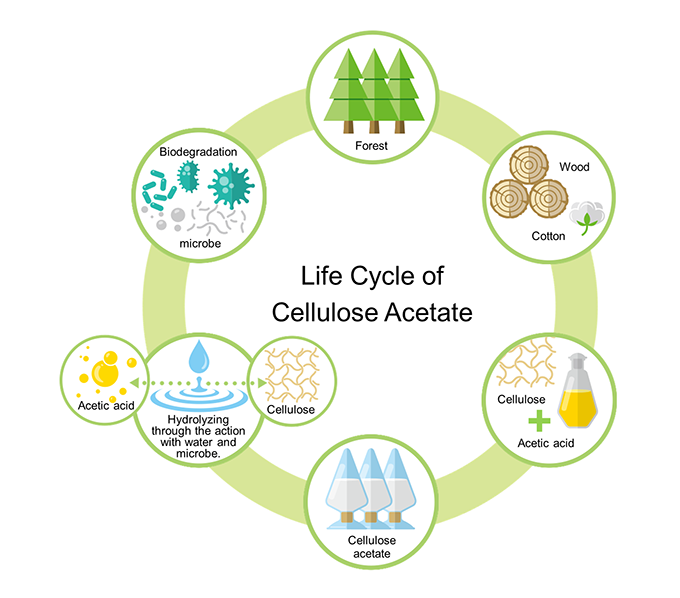

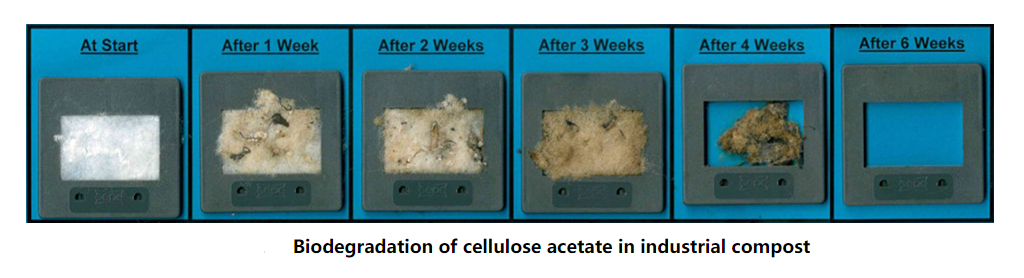

Cellulose acetate is made from natural materials and returns to nature after use.  Unlike most typical synthetic plastics, those made with cellulose acetate break down after use into cellulose and acetic acid by the action of water in the natural environment. These materials eventually return to the environment with no adverse impact. What’s more, water and microorganisms eventually decompose the cellulose into carbon dioxide and water that can be used to nourish plants once again.

Unlike most typical synthetic plastics, those made with cellulose acetate break down after use into cellulose and acetic acid by the action of water in the natural environment. These materials eventually return to the environment with no adverse impact. What’s more, water and microorganisms eventually decompose the cellulose into carbon dioxide and water that can be used to nourish plants once again. Compared with common synthetic plastics, however, cellulose acetate decomposes quite rapidly in both seawater and soil.

Compared with common synthetic plastics, however, cellulose acetate decomposes quite rapidly in both seawater and soil.

What are the advantages of cellulose acetate?

Cellulose acetate has the characteristics of colorless transparent, non-toxic, good gloss, high mechanical strength and good toughness. But the impact strength, electrical properties and dimensional stability are lower than other cellulose. Good light and heat stability, water resistance, fire resistance; But the softening point is low, the working temperature is less than 70℃; Resistant to dilute acid and oil, but soluble in acetone, methyl acetate and other solvents; Melt has good fluidity and is easy to be molded.

Cellulose acetate plate is natural, non-toxic and harmless and has very environmental protection efficiency, many hair ornaments are now using this kind of plate. Compared with other same type of jewelry raw materials, toughness, glossiness, texture and other aspects have significantly improved, is currently the first choice of high-grade jewelry manufacturers.

By using people- and earth-friendly cellulose acetate, we are contributing to the emergence of a sustainable society.

By using people- and earth-friendly cellulose acetate, we are contributing to the emergence of a sustainable society.