Green Package Material (GPM) serves as the foundation of eco-friendly packaging design.

In early storage and transportation packaging, natural environmentally friendly materials such as shredded paper, straw, wood shavings, and sawdust were primarily utilized as cushioning materials for goods. However, these cushioning materials, if improperly used, may pose risks such as self-ignition under certain conditions, dust generation, poor water resistance, susceptibility to moisture absorption, insect infestation, and even mold growth, significantly compromising their cushioning effectiveness. With the advancement of science and technology, a range of eco-friendly cushioning packaging materials has been gradually developed. Here are several types of green cushioning packaging materials widely used today.

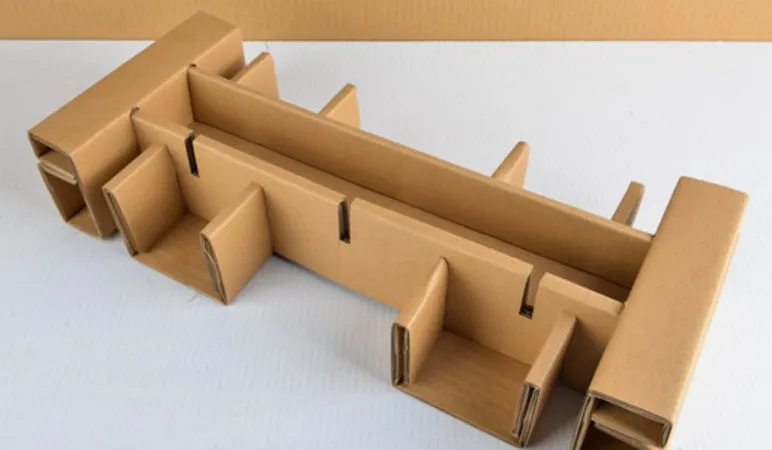

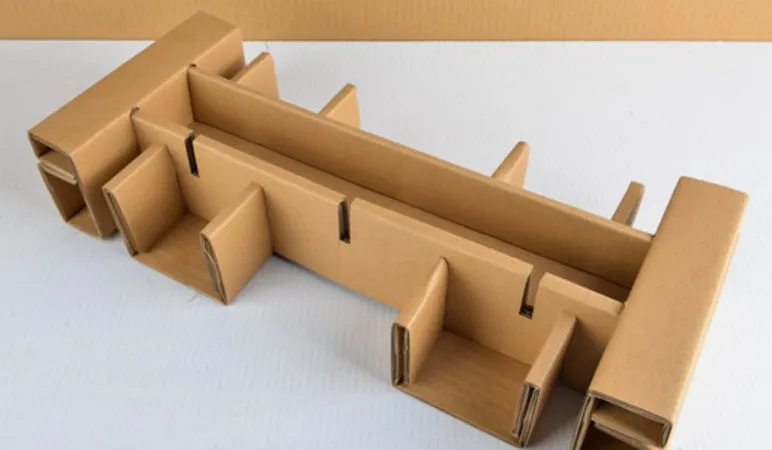

Corrugated cardboard is composed of linerboard (also known as facing) made of kraft paper and corrugated medium (fluting) sandwiched between them. By varying the number of layers of linerboard and medium, as well as the shape and size of the corrugation, different types of corrugated cardboard can be produced.

It boasts advantages such as excellent environmental performance, wide temperature suitability, low cost, convenient sourcing, mature production processes, and good processing properties. However, it suffers from poor flexibility and resilience. For interior packaging, three or five layers of corrugated cardboard can be directly used as cushioning pads. Additionally, corrugated cardboard can be fabricated into various shapes such as inserts, rings, dividers, liners, corner guards, and edge protectors.

Biodegradable plastics possess the characteristics of traditional plastics, yet they can degrade and return to the ecological environment in a non-toxic and harmless form after completion of their mission, facilitated by sunlight's ultraviolet rays or the action of microorganisms in soil and water.

The development of biodegradable plastics is a major trend in global technological advancement and represents a hot topic in modern packaging material research and development. Recently developed biodegradable foam plastic sheets contain at least 40% starch and a biodegradable component of at least 60%. With an expansion ratio of 30 times and a density of 0.033g/cm3, they exhibit excellent environmental adaptability. These materials can be used as cushioning packaging for precision instruments, high-end electronic appliances, and other applications.

Pulp molding utilizes plant fibers from waste newspapers, cardboard, and other paper materials as its primary ingredients. Through methods such as vacuum molding, hydraulic molding, and air compression molding, these fibers are rapidly and evenly deposited onto a mesh-like mold. After shaping into various forms, the product is then compacted, dried, and solidified, resulting in paper-based items that retain their shape over the long term.

Pulp molded packaging products feature geometric shapes that conform closely to the contours of the packaged items, providing excellent protection against shock, impact, static electricity, and corrosion. Their performance and efficacy make them suitable alternatives to foam plastic packaging products made from Expanded Polystyrene (EPS), PS, and PVC. They are widely used for inner lining packaging in industries such as electronics, mechanical components, industrial instruments, electrical tools, computers, household appliances, glassware, ceramics, and agricultural products.

Honeycomb cardboard is a novel type of board composed of a honeycomb-like paper structure as its core, sandwiched between linerboard and single-faced corrugated cardboard on its two sides. This innovative material minimizes material consumption, resulting in a lightweight and cost-effective solution, while offering high strength and rigidity. Its spatial structure surpasses that of corrugated cardboard and boasts excellent properties such as cushioning, vibration isolation, thermal insulation, and soundproofing. With special treatments, honeycomb cardboard can also be made flame-retardant, moisture-resistant, and waterproof, making it an economical and versatile material. Developed in recent years, honeycomb cardboard finds application in various packaging forms including honeycomb cartons, cushioning pads, honeycomb cores, and honeycomb trays.

Honeycomb cardboard has emerged as a novel green packaging material that saves resources and protects the environment.

-

Plant fiber cushioning packaging materials

Plant fiber cushioning packaging materials are a novel green environmental product developed in recent years. This product is made from plant fibers (such as waste newspapers, cardboard, and other plant fiber materials) along with starch additives. The new packaging material boasts advantages such as non-polluting the environment, simple manufacturing processes, low cost, and abundant raw materials, making it an ideal substitute for EPS and other foam plastic packaging materials. Currently, countries around the world have made various stages of progress in the research and development of plant fiber cushioning packaging materials.

The manufacturing process of plant fiber paper mainly focuses on foaming without the addition of chemical foaming agents. Instead, it utilizes steam to foam, forming granular foamed pulp. Experimental evidence has shown that after disposal, this cushioning material can be quickly decomposed by microorganisms and fungi. Its performance surpasses that of EPS foam plastics, as it is not only cost-effective but also environmentally friendly, with promising prospects for development.

EVA foam, made from Ethylene Vinyl Acetate (EVA), is a foam plastic product commonly used across various applications, particularly in the fields of cushioning packaging and protection.

It boasts the following characteristics and advantages: EVA foam is lightweight and sufficiently flexible, effectively cushioning and protecting packaged items from impacts and pressures. Its excellent shock absorption and cushioning properties reduce the impact on packaged items, preventing damage. EVA foam also exhibits good abrasion resistance and chemical corrosion resistance, maintaining the appearance and performance of packaging and being less susceptible to wear and tear during use. Its thermoplastic nature allows it to be molded into various shapes and sizes through processes such as hot pressing and injection molding, catering to diverse packaging needs. Some EVA foam products are made from recyclable materials, while others with special formulations possess biodegradability, decomposing into harmless substances under certain conditions, thus reducing environmental impact.

EVA foam finds wide application in packaging and protecting fragile items now, such as electronics, glassware, and ceramic products, ensuring their integrity during transportation and storage.

●●●

Currently, regions and countries such as Europe, the United States, Japan, South Korea, and Australia have enacted legislation to prohibit the import of industrial products packaged with foam (EPS), or they impose significantly higher environmental taxes to restrict and phase out imported products packaged with foam plastics, thus creating what is known as "green trade barriers". For instance, commodities entering the German market must apply for the "Green Dot" symbol, while those entering the French market require the "Vertical Line" symbol.

Therefore, developing green packaging aligns with global consumer trends and is beneficial for overcoming international green trade barriers. Moreover, it plays a proactive role in reducing product damage during distribution, improving the quality of packaging products, and enhancing the added value of goods.