Air cushion puff for beayty and cosmetic

- About air cushion powder puff products

Air cushion puff, as an important part of air cushion BB cream. Because it needs to contact with the face, and affect the makeup effect, more and more attention by the brand side. In the process of use, consumers often do not trust the brand side because of some defects of powder puff, which seriously affects product sales and brand image. As the brand side, because of the air cushion powder puff quality standards are not familiar, do not know how to choose high-quality powder puff, problems and do not know how to solve, is very troubled! Some brand square to go to the convenience, entrust package material factory or material body factory to purchase for you directly, package material factory or material body factory, often because the powder puff that purchases appears a problem and be questioned, bear joint and several responsibility even sometimes, also be very aggrieved!

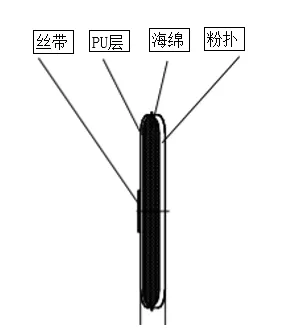

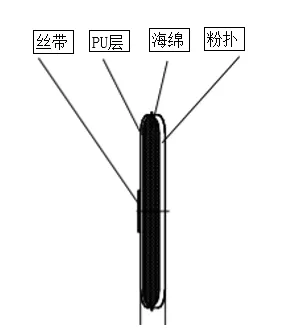

Air cushion powder puff is a kind of makeup tool, but also an important tool to take out the contents of air cushion products. It only takes a gentle dip to instantly shine, making makeup so convenient and simple. The base material of air cushion powder puff is made of three layers of materials bonded by glue, namely fabric layer, sponge layer and PU layer. After stamping molding, the ribbon on the car, the whole air cushion powder puff is formed.

2.Powder puff manufacturing technology

The fabric layer, sponge layer and PU layer are rolled together by water-soluble adhesive to form three-layer composite sheet with sandwich structure

The purpose of the drying treatment of three-layer composite sheet is to volatilize the water in the adhesive fully and stick the three-layer sheet firmly. The indoor temperature and drying time are the key factors affecting the composite quality. Note: in this step, glue bonding process must be selected. If hot melt adhesive process is used, although the speed is much faster, the product is prone to stratification, which affects the makeup effect.

The dry sheet is placed in the mold to press and seal the powder puff of a specific shape. This step has two key control parameters: heat sealing temperature, heat sealing time; One key component: punching die. The combination of the three plays a key role in sealing fastness and yield of powder puff. Note: the quality of the edge sealing process determines whether the powder puff will burst.

- car ribbon, disinfection, inspection, factory

The ribbon will be processed with special sewing machines, specifications and sizes meet user requirements.

- Powder puff product structure

- Fabric layer

NEOPORA Materials

Made in Korea. At present, the air cushion powder puff of Amore company of Korea uses this kind of fabric more. Its main characteristic is: do not absorb powder, do not put powder, go up makeup even and thin thoroughly. Anti chip, anti tear. No deformation in case of water, can be repeatedly cleaned. No phenol, no fluorescent agent, antibacterial, anti-mildew, with up to 99.9% inhibition effect on pneumococcus and Staphylococcus aureus, which are easily produced when contacting with skin surface.

Rubycell Materials

Origin is domestic. Domestic production of air cushion powder puff more use this fabric. Its surface is delicate, the texture is soft, the powder is pasted. No chip, with good extensibility. The downside: it tastes big. Will quickly absorb material, powder storage powder. Some time too long will turn yellow.

Import Rubycell materials

Made in Korea. Compared with domestic Rubycell material, due to different production process, imported Rubycell material surface is more delicate, completely solve the problem of fabric odor and cut marks. No powder absorption, no powder storage, makeup more comfortable.

Non-latex material

Origin is domestic. Domestic production of low-end air cushion powder puff, the use of this fabric. The surface of the fabric is rough, there will be powder absorption phenomenon, water will expand, can not be cleaned.

There are many kinds of sponges, Such as latex "natural rubber" and "synthetic rubber (NBR, SBR)", as well as polyurethane "Rubycell (wet foam polyurethane)", "Dry foam hydrophilic polyester polyurethane (Beautyblender)" and "Tera Venus (dry foam polyether polyurethane). Imported powder puff sponge layer for polyurethane material, producing area for Japan Inoue. Domestic sponge rebound insufficient, will lead to powder puff shape uneven.

Imported PU leather, Korea decheng company production. The price is higher, to make the air cushion puff will not crack, will not change color.

Domestic leather, also known as imitation imported leather. The price is low, unstable, and the air cushion puff is prone to cracking and discoloration.

Imported Korean ribbon: bright color, beautiful.

Domestic ribbon: mainly yao Ming ribbon and three ribbons. Compare with import ribbon, the difference is more obvious.

- powder puff and air cushion cartridge matching instructions

First of all, do not put in the air cushion powder puff, close the packaging material, at this time the packaging material issued close sound is normal. First confirm the diameter, powder puff diameter should be slightly smaller than the packaging material diameter, tolerance can be controlled within 1MM. Then confirm the thickness, put in 7MM, 6MM, 5MM air cushion puff in turn, close the packing material, the puff thickness of the first normal sound is the ideal thickness.

Note: When placing the air cushion puff, the ribbon should be aligned with the armrest of the packaging material.

4 Matters needing attention when purchasing powder puff

- Powder puff absorbs too much powder, and the makeup effect is not good

Detection method: The faster detection method is to put the powder puff flat on the desktop, drop a drop of water on the fabric layer, the air cushion powder puff, the water will immediately penetrate into the sponge layer. The air cushion puff that does not absorb powder does not penetrate for a long time. The more formal detection method is: simulated consumer use: on the air cushion BB cream sample, after pressing 20 times continuously, press more than one time on the back of the hand, the material should rarely penetrate into the sponge layer, let alone penetrate out of the PU skin on the back of the puff.

- PU skin cracking and discoloration

Detection method: Soak powder puff in 10% NaOH solution, seal it completely with sealed bag, soak for 24H, then remove the packing material. Qualified air cushion powder puff, PU cortex will not appear rupture, serious discoloration and other situations. Unqualified air cushion powder puff, will rupture discoloration.

Solution: abandon domestic leather and choose imported PU leather from Korean Deoksung Company.

Test method: A simple test is boiling water: place an air cushion puff in boiling water for 3-5 minutes. Poor quality powder puff, knead gently with the hand, fabric layer can and sponge layer separation. And good quality powder puff, fabric layer and sponge layer, as before.

Solution: abandon hot melt glue process, adopt imported glue process.

- the total number of bacteria exceeds the standard, powder puff is not antibacterial, not mildew resistance, phenol, fluorescent agent and so on

Detection method: Generally, the third party testing institutions are provided with detection reports.

As a cosmetic tool in contact with the face, people pay more and more attention to the safety of air cushion powder puff. Many cosmetics companies have gradually increased the detection requirements of phenol, fluorescent agents, bacterial indicators, etc., striving to do minimum or even harmless harm to human body.

5. Powder puff product display