The difference between linerless paper labels and traditional self-adhesive labels.

The difference between linerless paper labels and traditional self-adhesive labels.

The self-adhesive label, as an important commodity packaging, with its without brushing glue, not paste, without dip in water, easy to operate, wide applicable scope, labeling time saving and high level appearance fashionable whole world, and many other advantages, is widely used in food and beverage, household cleaning care, health care, electronic appliances, logistics, transportation and various industries such as industrial production.

In the process of the rapid development of self-adhesive labels, the disposal of waste base paper has been controversial. Traditional self-adhesive labels have two basic structures:surface material + base paper. When using, the surface material will be removed from the base paper and pasted to the material, very convenient. However, label manufacturers and customers gradually find that after traditional labels are used, the remaining base paper has no value, which is not only a waste of resources, but also cause environmental pollution. In order to solve this problem, label manufacturers through the improvement of process and technology, and eventually invented a self-adhesive label without base paper, lower carbon and more environmental protection -- linerless paper label.

Linerless paper label, as the name implies, is a self-adhesive label without liner paper.

The usage of traditional label surface material and base paper is 1:1. Without liner paper, it means that nearly 30% of raw materials are saved, the cost of storage and transportation is almost halved, the number of a roll of labels is doubled, the downtime for changing the roll is reduced, and the cost of traditional label treatment of waste base paper and environmental pollution are eliminated.

For manufacturing equipment, especially silicone oil and glue coating equipment requirements are high, ordinary label manufacturers are difficult to effectively use silicone oil and adhesive; More mature bottomless paper label shape is limited, generally rectangular; Labeling system is more complex than sticker labeling.

Linerless paper label is the natural evolution of self-adhesive label.

Linerless paper label is the natural evolution of self-adhesive label.On 30 May 2018, the European Parliament and the Council of the European Union stated in Directive 2018/852/EU that priority should be given to preventing waste generation at source. Bottomless paper label it directly converts the waste paper into film-covered surface material, bringing logistics convenience and comprehensive benefits for brand owners and printing plants. After using the bottomless paper label solution, the bottom paper can be reused directly. In fact, in the bottomless label solution, the base paper is reused as a film covering material after printing. In this way, the label does not require any additional film material, which not only protects the label product, but also improves productivity and production, while reducing shipping volume, but also saving at least 50% in transportation and storage costs.

Why choose linerless paper labels?

Why choose linerless paper labels?

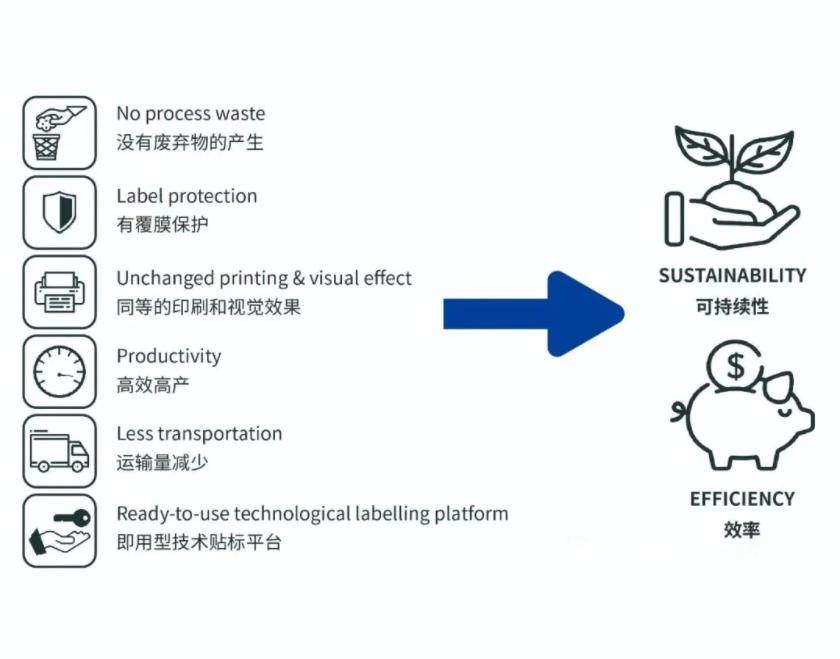

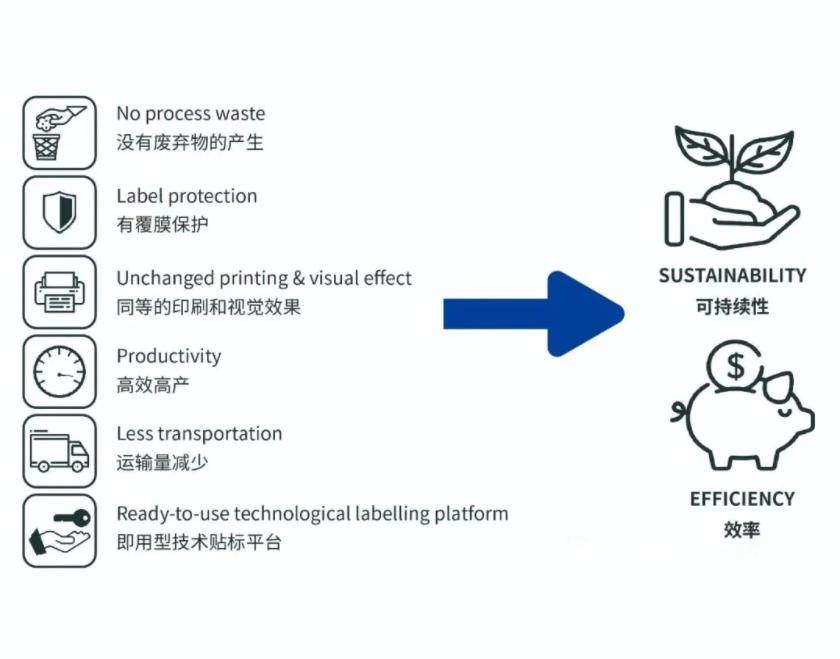

- Linerless paper label solutions combine technological innovation with sustainable development for many benefits. From production waste removal (no need to deal with the base paper or substrate) to reduced logistics footprint, the bottomless paper solution not only reduces the consumption of raw material resources, but also doubles the number of labels produced per roll of material. The result of these improvements is not only a reduction in carbon dioxide emissions, but also a virtuous cycle of development aimed at respecting the environment.

- Using a linerless paper label solution, the base paper is reused, no waste or substrate needs to be treated (reduces raw material consumption).

At the same time, are suitable for traditional printing technology and ink, in order to improve the printing speed (printing without stripping the substrate) and always provide a layer of film protection for your label products, making the label products more sustainable. The real elimination of waste brands, more environmentally friendly products.

The difference between linerless paper labels and traditional self-adhesive labels.

The difference between linerless paper labels and traditional self-adhesive labels.